Concentric butterfly valves are the most basic design and are also commonly called resilient-seated butterfly valves. The concentric butterfly valve is a standard or a general use butterfly valve. In this type of valve, the stem is centered in the middle of the valve disc, which is centered in the pipe bore. This valve typically has a rubber (or resilient) seat and relies on the disc having a high level of contact with the seat to effect a seal. The disc will contact the seat the earliest (±85°) during the 90° rotation.

During opening or closing, there are some parts of the disc that always in-contact or rubbing the seat. This arrangement will make the seat experience friction each time the valve is operating. In a typical application, this concentric butterfly valve is limited to class 150 due to its seat design.

Valves lined with different anti-corrosion materials can be applied to corrosive working conditions.

The design is subjected to API standard according to API609.

Special working conditions for this series valves:

- Water condition;

- Gas condition;

- Corrosive working condition;

- High service long life condition.

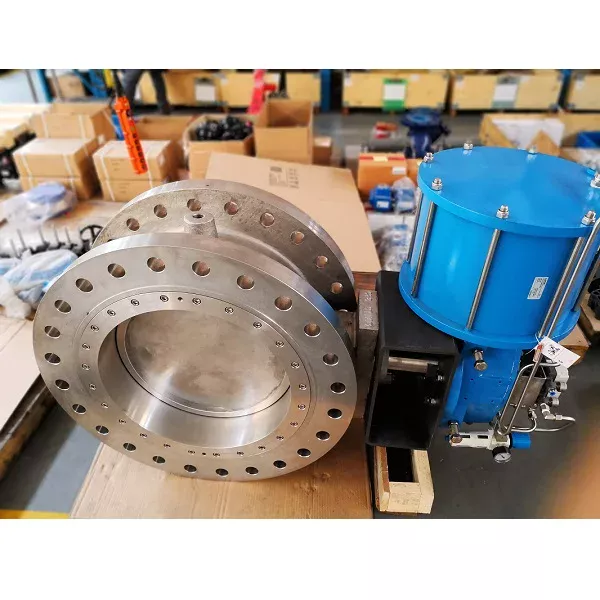

Size: NPS 1.5″~120″

Rating: 150LB

End type: Wafer, Flange, Lug

Material: Cast Iron, Carbon Steel, Stainless Steel, other material according to requirement

Standard:

- Design and manufacture: API609

- Inspection and test: API598

- End connectin: ASME B16.5, ASME B16.47, ASME B16.25 BW

- End to end: API609, ANSI B16.10

- Pressure-temperature rating: ASME B16.34